Core technologies

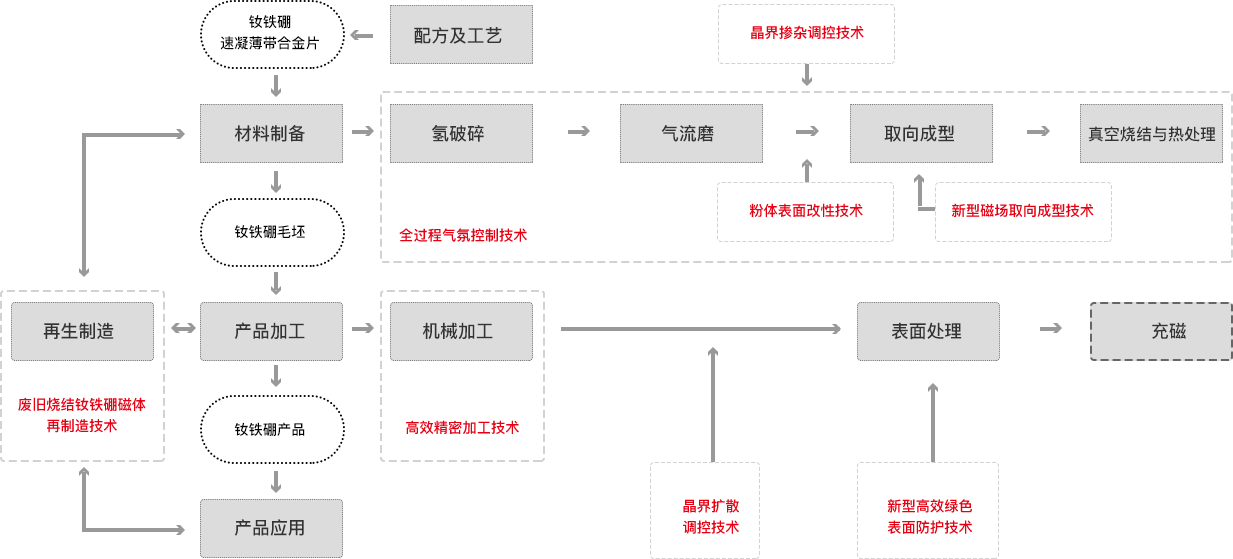

After years of technological innovation, the company has formed a core technology system of the whole production process of sintered NdFeB magnets covering many aspects such as magnet preparation(production), machining, surface protection and regenerative(recycling) manufacturing. Through the above-mentioned core technologies, the company achieves improving magnetic performance and service characteristic of the products and saving resource and cost.

Representation of advancement

Sintered NdFeB permanent magnets are mainly composed of the main phase and the grain boundary phase located between the grains of the main phase. Although the grain boundary phase accounts for less in the material, it largely determines the properties of the material and the final product.

On the basis of in-depth study on the influence of grain boundary phase on the properties of sintered NdFeB permanent magnet materials, the company independently innovates and develops the grain boundary doping control technology(Grain boundary Diffusion technology) of various substances. By introducing different types and quantities of substances directly into the grain boundary region of the magnet, the substances react with the original grain boundary phase during sintering and subsequent aging, so as to change the composition and structure of the grain boundary phase, thus improving the performance of the magnet and reducing the addition amount of heavy rare earth in the high coercivity magnet.

The grain boundary doping control technology(Grain boundary Diffusion technology) is the key core technology for the company to develop the sintered NdFeB magnets of ultra-high magnetic properties series, high thermal stability series and low weight rare earth series, as well as the core technology for recycling waste magnets.

Representation of advancement

The properties of sintered NdFeB permanent magnets are affected by the content of nitrogen, oxygen and carbon in the materials. The high content of nitrogen, oxygen and carbon consumes the rare earth elements in the materials, resulting in the performance degradation such as the decrease of the coercivity, temperature resistance and corrosion resistance of the materials.

The company innovates and develops a number of control technologies and devices for nitrogen content, oxygen content and carbon content of the magnets, forming the whole process atmosphere control technology covering the processes such as hydrogen decrepitation, jet milling, magnetic field forming, sintering and annealing, effectively controlling the nitrogen, oxygen and carbon content in the magnets, reducing the consumption of rare earth elements, increasing the utilization rate of rare earth elements and improving comprehensive performance of products. Under the condition that other properties are basically unchanged, the coercivity of the materials increases by 5~10% on average, and the corrosion weight loss of the materials decreases by more than 20% on average.

The whole process atmosphere control technology is an important auxiliary technology for the production and manufacture of the whole series of products of the company.

Representation of advancement

Sintered NdFeB permanent magnetic materials are produced by powder metallurgy process. The NdFeB alloy micron powder is an important intermediate product in the manufacturing process of sintered NdFeB permanent magnet materials. The properties of the powder determine the final properties of the magnets to a great extent.

The company has innovated and developed a variety of surface modification technologies of NdFeB alloy powder, including physical vapor deposition technology of heavy rare earth metal film layer, powder surface diffusion modification technology, chemical synthesis film modification technology, etc. Through the powder surface modification, the fluidity and oxidation resistance of the powder are improved, the anisotropy field of the powder surface layer is increased, and the coercivity of the materials is improved finally.

The original surface modification technology of NdFeB powder in the industry is mainly to add chemical reagents such as antioxidants and lubricants to improve the oxidation resistance and fluidity of the powder, but seldom involves the use of powder modification to directly improve the coercivity of the materials. The powder surface modification technology developed by the company improves the fluidity and oxidation resistance of the powder while improving the anisotropy field of the powder surface layer, finally improving the coercivity of the materials, constituting one of the key technologies for the preparation of high-performance sintered NdFeB materials of the company.

Representation of advancement

Magnetic field alignment molding is a key process in the production of sintered NdFeB. The uniformity of powder alignment and the homogeneity of compact density after molding directly affect the main magnetic properties and machining yield of magnets.

Through technological innovation in mold design, powder addition, alignment magnetic field, etc., the company has developed the alternating magnetic field alignment molding technology capable of improving powder alignment uniformity and the powder adding technology capable of improving powder filling homogeneity and powder alignment uniformity, and has designed and developed various new molds capable of improving magnet alignment uniformity and reducing magnet missing angle rate, thus improving the main magnetic properties and good quality rate of high-performance sintered NdFeB magnet products of the company.

In the industry, the uniformity of powder alignment is mainly improved by means of improving the magnetic field strength and powder fluidity. The company improves the powder alignment uniformity through integrated innovation of technology and equipment, and the improvement effect is better than that of the original method. Compared with the original method, the remanence of the materials is increased by more than 0.2 kGs on average and the BH max is increased by more than 0.5 MGOe on average. The new magnetic field alignment molding technology is an important auxiliary technology for the production and manufacture of the whole series of products of the company.

Representation of advancement

The composition and structure of the grain boundary phase directly affect many properties of the magnets. By introducing the heavy rare earth elements into the grain boundary phase and the grain surface layer of the main phase by means of grain boundary diffusion, the coercivity of the materials can be improved significantly without reducing the remanence of the materials.

The company has innovated and developed a number of grain boundary diffusion control technologies for sintered NdFeB magnets, mainly including: deposition of heavy rare earth metal coating + diffusion technology on magnet surface by electrodeposition, deposition of heavy rare earth metal coating + diffusion technology on magnet surface by laser cladding technology, etc. The development and application of these technologies significantly improve the coercivity of the magnets, reduce the heavy rare earth content of the high coercivity magnets, and constitute the key technologies of the company to prepare ultra-high performance sintered NdFeB magnets and low heavy rare earth sintered NdFeB magnets. The common grain boundary diffusion control technology in the industry mainly includes two steps: the contact between the diffusion source and the magnets to be diffused, and the diffusion annealing. Compared with other grain boundary diffusion control technologies in the industry, the innovation of this technology is mainly embodied in: combining the contact step between the diffusion source and the magnets to be diffused with the surface protection step of the magnets, and realizing the contact between the diffusion source and the magnets to be diffused while performing surface protection treatment.

Representation of advancement

Sintered NdFeB magnets often need to be assembled together with other parts for use. The assemblies’ precision and speed of assembly are directly affected by the machining precision of magnets, especially the machining of profiled magnets and the machining of magnets used in the automatic assembly process with high precision requirements. Machining precision and machining efficiency are important indexes of sintered NdFeB magnet processing.

Aiming at the high-efficiency precision machining requirements of sintered NdFeB magnets, the company has researched and developed methods and devices for different machining requirements, including processing methods and special fixtures for inclined tile products with special shapes, fast clamping fixtures for cylindrical product slicing, the marking device for radial magnetized products during processing, the processing device for products requiring high perpendicularity, etc., which improves the machining precision and efficiency of sintered NdFeB products and meets the requirements of downstream automatic assembly lines and assembly of high-precision parts and components.

Representation of advancement

The main reason to decide the ability of surface protection for Neodymium magnets lies in matrix connectivity, corrosion resistance and abrasive resistance, which are critical characteristics. In order to meet different magnet application requirements , it is necessary to develop a variety of efficient and green surface protection technologies.

The company has innovatively invented high corrosion resistance coating technology of rare earth permanent magnet materials. The developed coating adhesion enhancement technology, corrosion resistance improvement technology and wear resistance improvement technology, etc. have significantly improved the protection capacity of the existing coating layer and met the application requirements of many strong corrosive environments.

The company has innovated and developed a variety of new surface green coating technologies and supporting devices for sintered NdFeB magnets, including physical vapor deposition aluminum coating, spraying zinc aluminum coating, chemical synthesis temporary protective organic coating, laser cladding metal coating, fixtures for physical vapor deposition of sintered NdFeB magnet surface and the automatic turning device for spraying of sintered NdFeB block magnet surface, etc., which significantly reduce the environmental cost of magnet surface protection under the premise of ensuring that the coating protection capability is not lower than that of the existing coating layer.

Representation of advancement

Rare earth is non-renewable strategic resource. There are a lot of rare earth elements in the scraps produced in the production and manufacture of sintered NdFeB and scrap old magnets after use, which belong to important secondary resources.

The company has independently innovated and developed the surface decontamination technology after demagnetization of magnet oil, the rapid removal technology of surface coating, and comprehensively uses the self-developed grain boundary doping control technology, the whole process atmosphere control technology and other magnet preparation technologies to directly remanufacture the waste sintered NdFeB magnets into the regenerated sintered NdFeB magnets. Compared with the original magnets, the recovery rate of the main magnetic properties exceeds 95%, realizing the short-process remanufacturing of waste sintered NdFeB block magnets.

Compared with the recycling technology of waste magnets commonly used in the industry, the recycling and remanufacturing technology of sintered NdFeB magnets developed by the company is characterized by short process, high efficiency, environmental protection and high recovery rate; the manufacturing cost of regenerated magnets obtained by remanufactured sintered NdFeB magnets is lower than that of the ordinary magnets with the same properties.